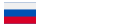

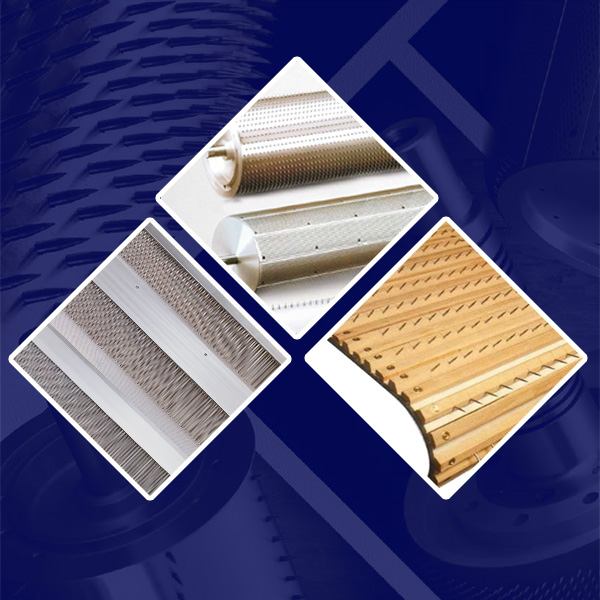

Pinned Rollers

We offer a diverse range of Pinned Rollers tailored for use in fibre preparatory machines from renowned

manufacturers such as Rieter, Trützschler, Marzoli, Crosol, and LMW. Our Pinned Rollers are meticulously crafted to

meet the specific requirements of each machine make, ensuring seamless integration and optimal performance in

fibre processing operations.

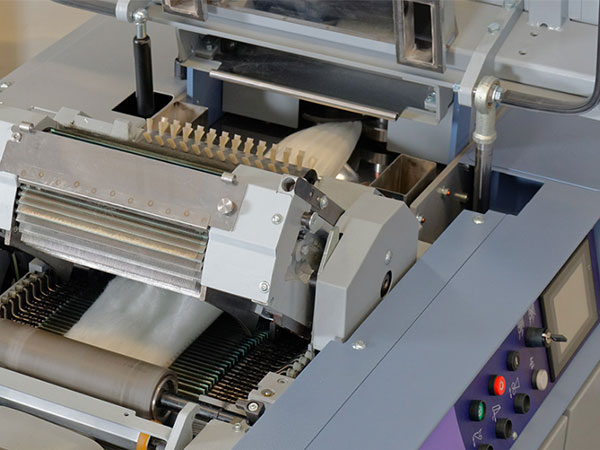

Special Characteristics of Our Pinned Rollers:

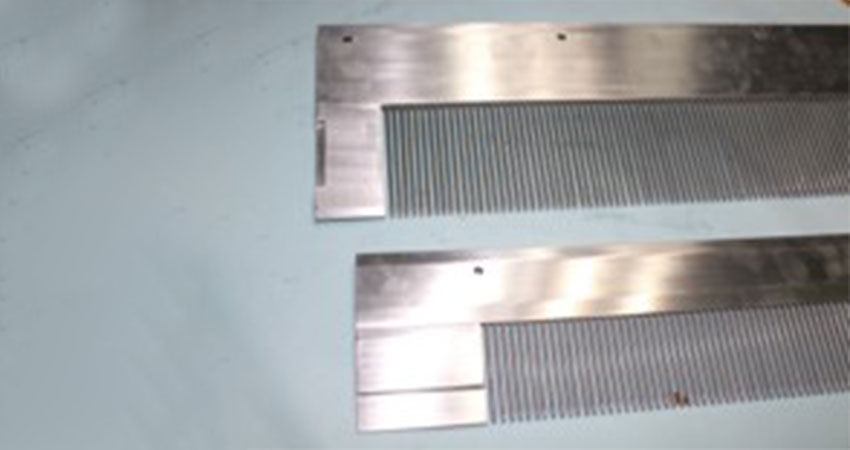

1. Accurate Pin Sizes: Precision-engineered pins with smooth tapers ensure proper fibre guidance and minimal

damage. Pin projection tolerance within 0.01 mm range is maintained using specially designed machines for

precise performance.

2. High-Grade Aluminium Construction: Components are made from a special grade of aluminium, providing

exceptional durability to withstand torques and stresses of high-speed operations.

3. Dynamic Balancing:Each roller undergoes dynamic balancing for longer operating life, reducing vibration

and wear, enhancing overall performance and reliability.

4. Strict Fitment Dimensions: Adherence to strict fitment dimensions ensures easy mounting on machines

without issues, simplifying installation and maintenance processes, minimizing downtime, and ensuring

continuous operation.

James Mackie & Sons

James Mackie & Sons Fraser

Fraser Bolelli

Bolelli Jinde,China

Jinde,China DS (Germany)

DS (Germany) Linimpianti

Linimpianti Sant Andrea

Sant Andrea Warner & Wasey

Warner & Wasey Marzoli

Marzoli LMW

LMW Reiter

Reiter Trutzschler

Trutzschler LaRoche

LaRoche Margasa

Margasa Marlasca

Marlasca Balkan

Balkan Golden Eagle Mackie

Golden Eagle Mackie J F Low

J F Low Gardella

Gardella Jurgens

Jurgens Rieter

Rieter Crosrol

Crosrol Various Chinese Machines

Various Chinese Machines Dellorow Villani

Dellorow Villani NSC Schlumberger

NSC Schlumberger Cognetex

Cognetex OKK

OKK Textime

Textime

Whatsapp Us

Whatsapp Us Call Back Request

Call Back Request Call Us

Call Us LinkedIn

LinkedIn Facebook

Facebook