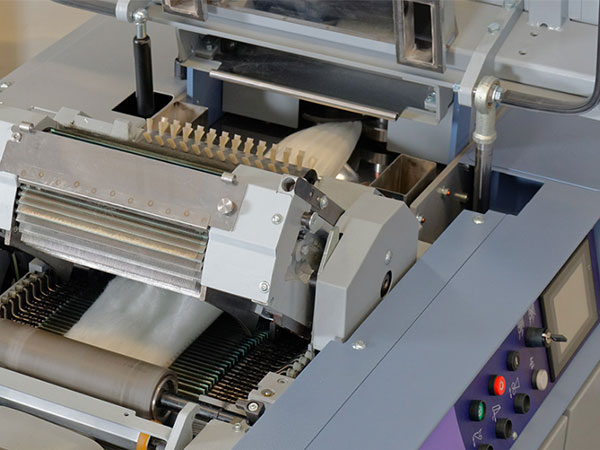

We provide machined castings tailored to meet the specific requirements of our customers. These castings

are available in a variety of materials, including:

1. Steel:

Known for its strength, durability, and versatility, steel castings are suitable for a wide range

of applications across various industries.

2. SG & Malleable Iron:

SG (Spheroidal Graphite) iron, also known as ductile iron, offers high strength,

toughness, and ductility, making it ideal for applications requiring impact resistance and fatigue

strength. Malleable iron, on the other hand, provides excellent machinability and wear resistance.

3. Cast Iron:

Cast iron castings are valued for their excellent machinability, damping capacity, and

thermal conductivity. They are commonly used in applications requiring high resistance to wear and

corrosion.

4. Non-Ferrous Metals & Alloys:

Materials such as aluminium, bronze, brass, and copper alloys are

used for castings requiring lightweight properties, corrosion resistance, and electrical conductivity.

By offering machined castings in a variety of materials, we ensure that our customers can find the right

solution to meet their specific needs and applications, whether it's for automotive, aerospace, machinery,

or other industries.

Bevel gears are manufactured using bevel generators, ensuring precise tooth profiles and accurate geometry for

smooth and efficient power transmission in bevel gear systems.

Our range of castings encompasses a wide spectrum of specifications and capabilities:

Weight Range: Our castings span from 2 kg to 1000 kg, catering to various application needs and

requirements.

Size Range: Diameter capability extends up to 1000 mm, with a maximum length of 1200 mm, providing

versatility for a range of projects.

Investment Grade Castings: For specialized applications, we offer investment grade castings in special alloys,

ranging from 0.100 kg to 5 kg, ensuring precision and performance where it matters most.

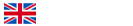

Machining Facilities:

Our machining facilities include:

- Turning

- Drilling

- Boring

- Milling

- Grinding (external & internal)

These capabilities allow us to provide finished components that meet exact specifications and tolerances.

Additional Processes:

In addition to machining, we offer a range of additional processes to enhance performance and functionality:

- Through Hardening

- Case Hardening

- Dynamic Balancing: We can dynamically balance impellers and rollers to ensure smooth operation and

minimize vibration.

We also provide comprehensive assembly operations, leveraging our expertise to offer complete solutions to our

customers.

With our extensive range of capabilities and processes, we can meet diverse customer needs, from basic

components to intricate assemblies, ensuring quality, precision, and performance in every product we deliver.

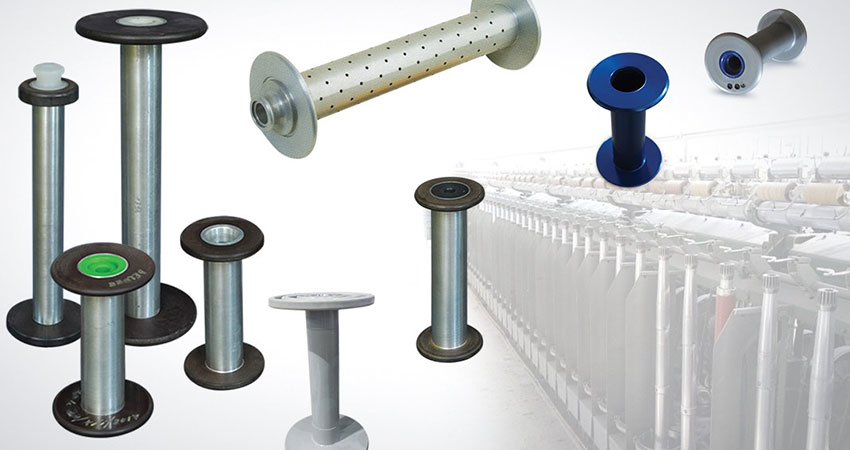

James Mackie & Sons

James Mackie & Sons Fraser

Fraser Bolelli

Bolelli Jinde,China

Jinde,China DS (Germany)

DS (Germany) Linimpianti

Linimpianti Sant Andrea

Sant Andrea Warner & Wasey

Warner & Wasey Marzoli

Marzoli LMW

LMW Reiter

Reiter Trutzschler

Trutzschler LaRoche

LaRoche Margasa

Margasa Marlasca

Marlasca Balkan

Balkan Golden Eagle Mackie

Golden Eagle Mackie J F Low

J F Low Gardella

Gardella Jurgens

Jurgens Rieter

Rieter Crosrol

Crosrol Various Chinese Machines

Various Chinese Machines Dellorow Villani

Dellorow Villani NSC Schlumberger

NSC Schlumberger Cognetex

Cognetex OKK

OKK Textime

Textime

Whatsapp Us

Whatsapp Us Call Back Request

Call Back Request Call Us

Call Us LinkedIn

LinkedIn Facebook

Facebook