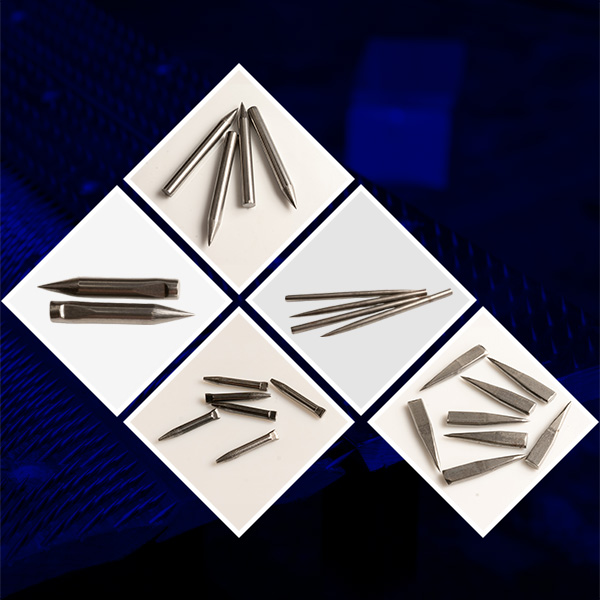

Key features of our pins:

1.Precise Dimensions:

Our pins are manufactured to exacting standards, ensuring consistent and accurate dimensions essential for reliable performance in various applications.

2. Uniform and Correct Heat Treatment:

Each pin undergoes uniform and appropriate heat treatment tailored to its specific application. This ensures optimal hardness, toughness, and durability, enhancing the pins' resistance to wear and deformation.

3. Fine Polish:

Pins are meticulously polished to a smooth finish, reducing friction and minimizing damage to fibers or other materials they come into contact with during operation

4. Correct Taper for Fiber Guidance:

The pins are designed with the correct taper to facilitate smooth fibre guidance, preventing snagging or entanglement, and promoting longer working life for both the pins and the machinery they are used in.

5. Wide Range of Sizes:

Our pins are available in a comprehensive range of sizes to accommodate diverse applications. This includes diameters ranging from 0.5mm to 14mm and lengths from 4mm to 250mm, providing flexibility to meet various customer needs and preferences.

6. Material Options:

Pins are crafted from high-quality materials such as Hi Carbon Steel, Stainless Steel, and other alloys, ensuring compatibility with different operating environments and requirements. Additionally, non-ferrous metals can be used as per customer specifications, offering versatility and customization options.

Pins are crafted from high-quality materials such as Hi Carbon Steel, Stainless Steel, and other alloys, ensuring compatibility with different operating environments and requirements. Additionally, non-ferrous metals can be used as per customer specifications, offering versatility and customization options.

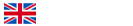

Applications:

Pins for Wool and Synthetic Spinning

- Gill Pins (Flat or Round)

- Comber Pins

- Cylinder Pins

- Top Comb Pins

- Feed Comb Pins

- Porcupine Pins

Pins for Jute, Flax & Sisal Spinning

- Hackle Pins

- Card Pins

- Gill Pins (Flat or Round)

- Double Taper Pins

Pins for Silk & Ramie Spinning

- Gill Pins (Flat or Round)

- Cylinder Pins

Pins for Cotton Spinning

- Comber Pins

- Cylinder Pins

- Top Comb Pins

Pins for various Textile applications

- Pins for Stenter Pin Plates

- Pins for Lags of Tearing Machines (Flat or Round)

- Pins for Spiked Lattices

- Pins for Weaving Temples

Pins for other industrial application

- Pins for Perforation and Fibrillation

- Pins for Tobacco Carding

- Pins as per customer's requirements

James Mackie & Sons

James Mackie & Sons Fraser

Fraser Bolelli

Bolelli Jinde,China

Jinde,China DS (Germany)

DS (Germany) Linimpianti

Linimpianti Sant Andrea

Sant Andrea Warner & Wasey

Warner & Wasey Marzoli

Marzoli LMW

LMW Reiter

Reiter Trutzschler

Trutzschler LaRoche

LaRoche Margasa

Margasa Marlasca

Marlasca Balkan

Balkan Golden Eagle Mackie

Golden Eagle Mackie J F Low

J F Low Gardella

Gardella Jurgens

Jurgens Rieter

Rieter Crosrol

Crosrol Various Chinese Machines

Various Chinese Machines Dellorow Villani

Dellorow Villani NSC Schlumberger

NSC Schlumberger Cognetex

Cognetex OKK

OKK Textime

Textime

Whatsapp Us

Whatsapp Us Call Back Request

Call Back Request Call Us

Call Us LinkedIn

LinkedIn Facebook

Facebook